Two Ways To Successfully Heat Print around Zips

Two Ways To Successfully Heat Print around Zips

To run a successful print business, you need to be confident decorating all garment types. Even apparel with pockets, zips and other obstructions. So what do obstructions have to do with running a successful print business?

Obstructions on the heat press platen, cause pressure disruption. Pressure disruption can lead to giving your clients poorly applied heat transfers, losing business and getting a bad reputation that may impact referral business in the future.

While it's true that if you don't apply the correct amount of heat for the correct amount of time, your transfer will not adhere, today we're focusing on the other part of the recipe that is vital for accurate transfer application; heat press pressure.

What is heat press pressure?

Heat Press Pressure is the measure of force that your heat-applied material is being pushed into the garment you're trying to apply it to. Every heat transfer requires a specific recipe for application and that includes a recommended pressure reading. If you don't apply it with the recommended pressure, you're not following the instructions properly and risking offering your customer a garment that may not withstand going in the wash. When pressure isn't applied evenly and accurately to a transfer, it creates pockets between the transfer and the garment where water can seep in and separate it further from the garment. Meaning the transfer might bubble or peel off.

So to avoid it, you just follow the recipe right? Right. Well.. almost.

First of all, you need an accurate measure of pressure. So using a heat press with a pressure readout like the Hotronix Auto Open is best for this. That way you know for sure that if your recipe says the transfer needs to be applied at a 4, your heat press is reading a 4.

But secondly, you need to be able to ensure you have a smooth and flat print area.

What does this mean?

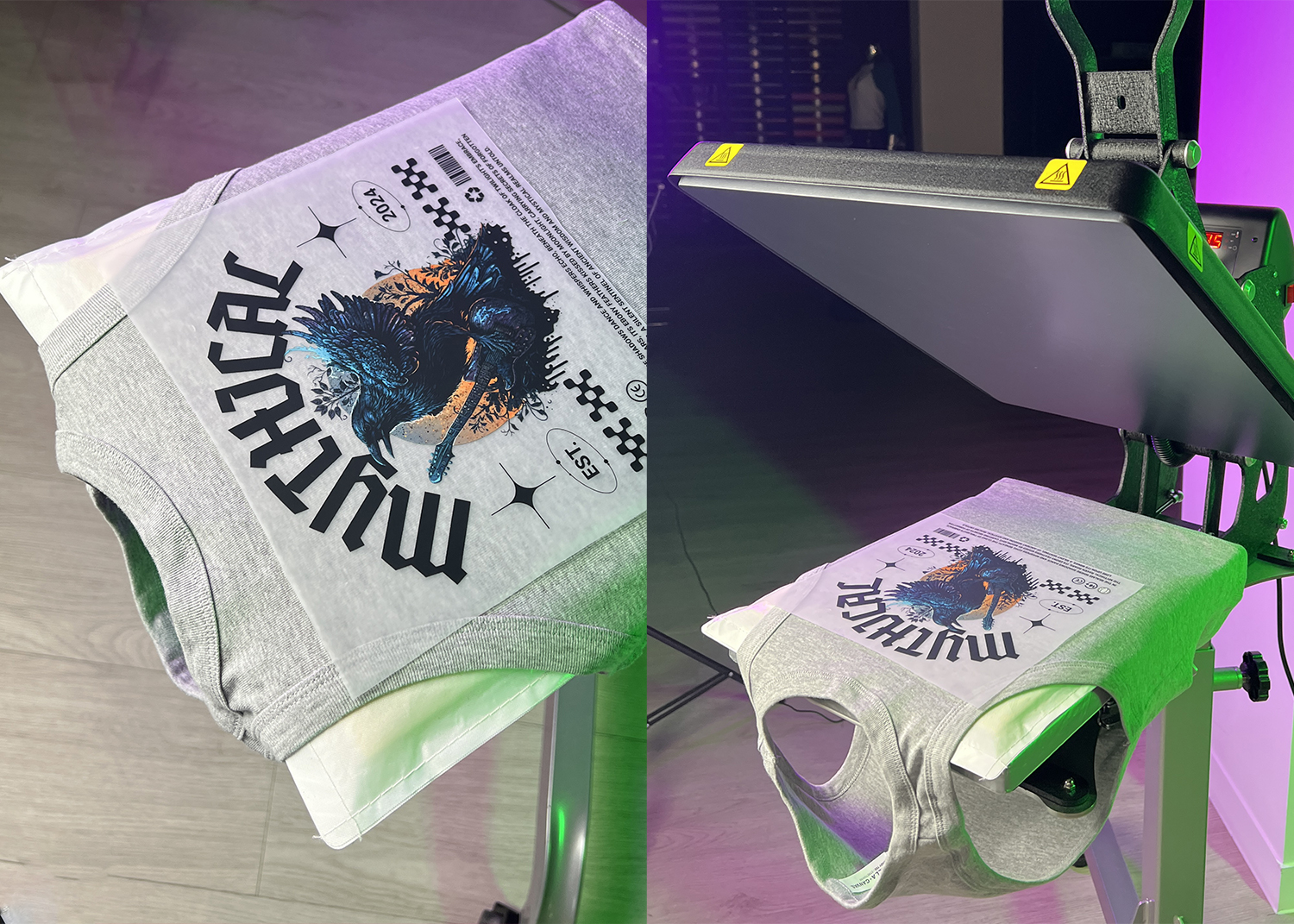

When you place your garment onto the platen, there must be no seams, collars, zips or pockets under the heat press. If there are, this will disrupt your pressure readout.

Because every heat press takes its pressure reading from the the thickest part of the garment on the platen, that means that the lowest part where your transfer is placed, will not recieve the correct heat or pressure distribution.

There are two ways that you can remove obstructions from the print space, the first of which is to use a heat press accessory.

Method One: Heat Print Pillows

These Non-Stick Pillows are placed into a garment or on a platen to allow the specific print area to be isolated. They allow thicker obstructions like zips or seams to sink into the pillow, letting the heat transfer rise above and receive an accurate application. Giving you accurate pressure for a high-quality and long-lasting finish.

As you can see in this image, the thick collars will sink into the pillow to allow the chest placement to be printed accurately

Method Two: Quick Change Lower Platens

The Hotronix heat press collection offers heat printers a unique advantage against other heat press brands, in the Interchangeable Lower Platen Collection.

This is made up of 15 different sized platens that are designs to help you isolate any print space for accurate application.

Simply, pull the lever, take your current platen off, put a smaller platen on and print your garments

If you want a more indepth explaination, watch both of these methods in action below: